Talking Thorium at Copenhagen Atomics

If the "Waste Burner" reactor takes off, there might literally not be enough nuclear waste in the world.

“First they ignore you, then they laugh at you, then they fight you, then you win.” That quote by Mahatma Ghandi hangs beside the desk of Copenhagen Atomics co-founder Thomas Steenberg. It’s for a good reason. Nuclear energy is literally illegal in Denmark. As in, there’s a 1985 resolution banning nuclear power plants. It must take a certain kind of a believer to work on a nuclear startup under such conditions, as the four co-founders did 8 years ago. They did so because they believe that thorium, the other spicy rock, can change the world.

I was lucky enough to drop by their Copenhagen HQ for a tour. Would it be enough to make a thorium-believer out of famously uranium-pilled Angelica?

The company is working on just one model, a 100MW thorium molten salt reactor they call the Copenhagen Atomics Waste Burner, designed to fit in a 40-foot shipping container. Since CA is using a build-own-operate model, the customer won’t be buying the reactor…just the product: heat. While electricity generation is the likeliest application, direct industrial uses can be intriguing as the temperature goes up to 700C. Pink hydrogen and synfuel production comes to mind. “It’s really up to the customer what they do with that heat,” said CFO Mike Christiansen, “we’re agnostic.”

By the way, the reason it’s called the Waste Burner is because the thorium “breeder” cycle needs an initial source of neutrons to get started, kind of like a sourdough starter. After that though, it just keeps going…and going…and going…(just like a sourdough). The “sourdough starter” Copenhagen Atomic wants to use is literally nuclear waste, the nasty stuff that you usually have to keep safe for at least 100,000 years. The resultant waste is still radioactive, but only needs to be kept safe for around 300 years, a dramatic reduction, dangling the tantalizing prospect that the nuclear waste problem that hangs over the entire industry can be solved.

“In fact, if this takes off there wouldn’t be ENOUGH waste in the world,” said Christiansen. (Luckily other sources of neutron like enriched uranium will work too.)

Steenberg was the co-founder I wanted to talk to the most because he’s the chemist, and as I understand it, the biggest bugbear plaguing molten salt reactors of all kinds is corrosion. The Idaho National Laboratory recommended that we should look for a new alloy strong enough to stand up to the triple abuse of high heat, corrosion and bombardment by radioactive particles over a period of years.

“Corrosion? We’ve solved it,” said Steenberg, “it wouldn’t be a problem to use stainless steel.”

But how?

Building loops and drying salt

Not a single speck of thorium is allowed at Alfa Laval Innovation House, the incubator housing 22 startups including Copenhagen Atomics’ current offices and experimental facilities. So what have they been up to? For one, how to get salt to be really, really, REALLY dry.

“We’ve achieved oxide levels below 20 parts per million,” said Steenberg. In fact, highly-purified salts are now a product for CA, who sells them to customers including nuclear fusion startups, whose requirement for salt purity is even higher. Supply outpaces demand, with CA only able to produce 500kg of the superdry stuff monthly, to ramp up soon to a tonne a month.

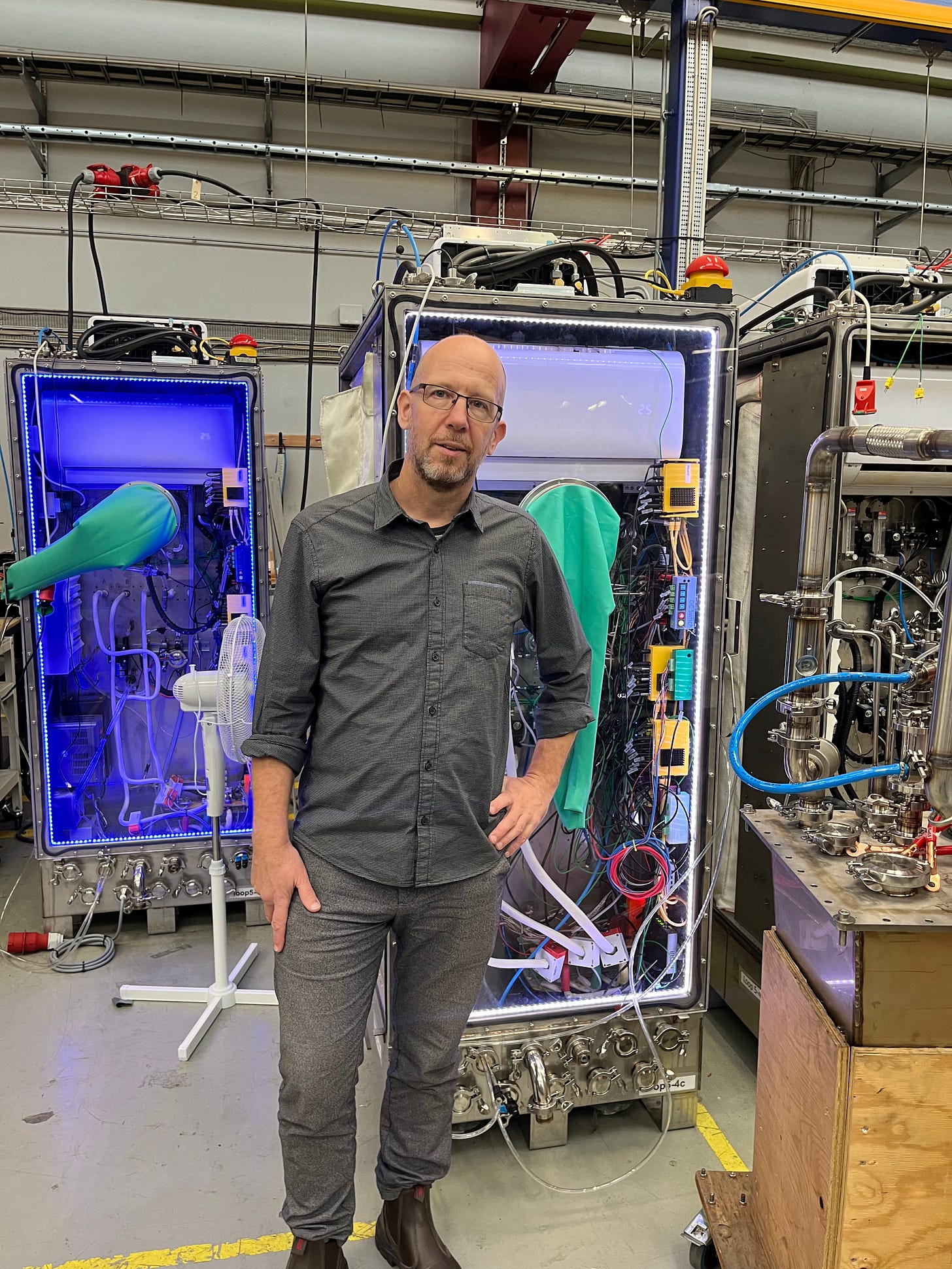

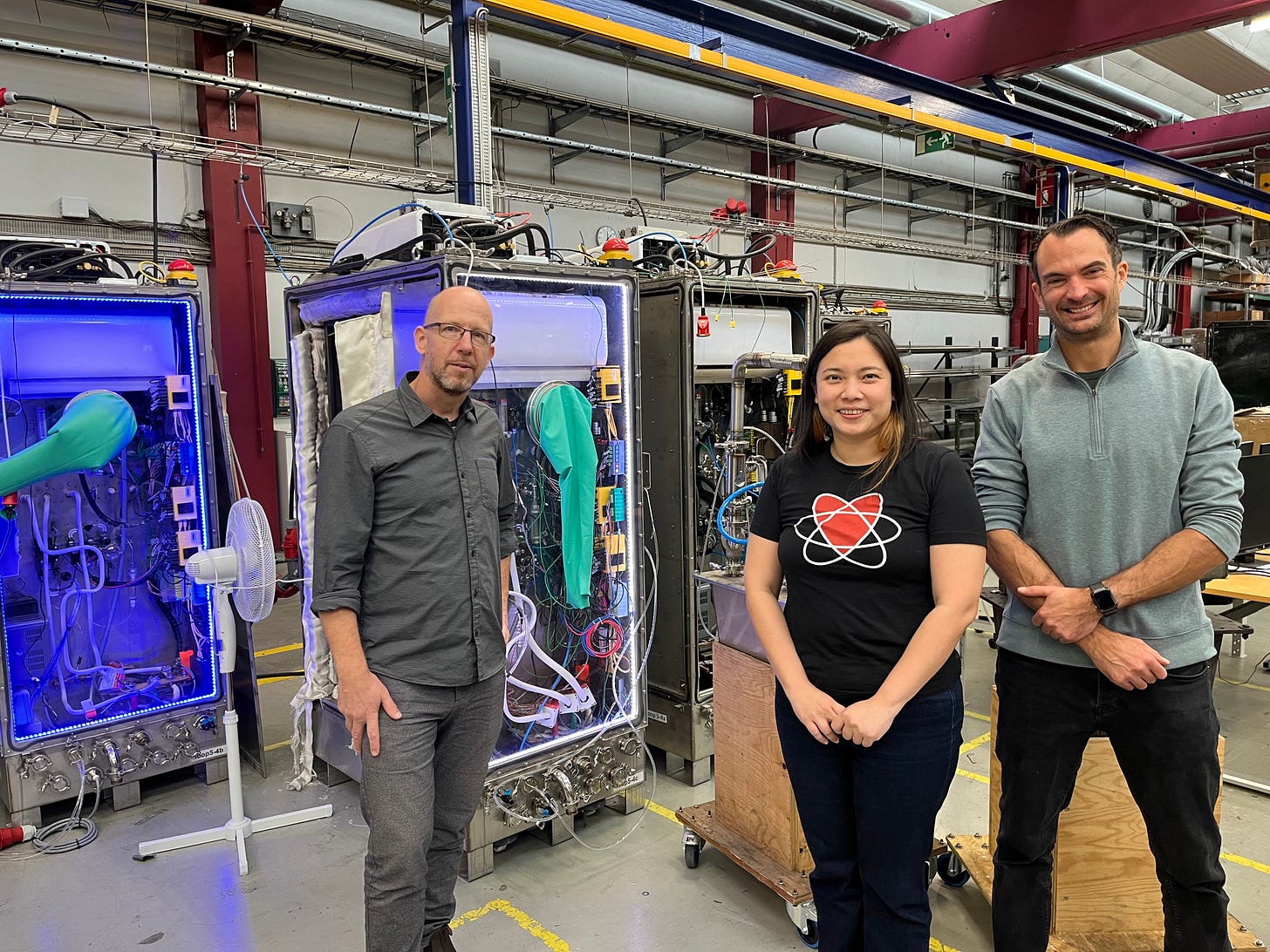

The other thing the CA team have been building are molten salt “loops”. You can see them behind Steenberg’s photo above. The side facing us is the cooled panel for instruments and such, but all the action goes on in the heavily insulated hot box in the back, where the loop itself actually sits. It can circulate 80 liters of molten salt of all kinds for material and chemistry experiments. The loops are also for sale, but instead of a moneyspinner they are seen by the team as a valuable way to build relationships with universities and research institutions all over the world. By the end of a year, a 1MW-sized test “reactor” will be running with molten salts.

By avoiding actually working with radioactive materials, CA has been able to sidestep dealing with regulators while they worked on the “molten salt” part of the molten salt reactor. But at some point, you can’t test a nuclear reactor without radioactivity. To do that, Copenhagen Atomics must find a host country where their reactor can finally go nuclear.

Going nuclear…but where?

The reason why Copenhagen Atomics thinks their reactors will work is because of pioneering work done at the Oak Ridge National Laboratory back in the 60s. In fact, the vintage video the ORNL produced back in the day is still the best introduction to the technology. The reactor ran for four years and showed that yes, molten salt reactors can be done. The computer models that CA uses to model the behavior of fission activities in molten salts come from Oak Ridge. But there will be no going home.

The CA team have ruled out the US as a potential host country because there is already a lot of competition for SMRs and the regulatory regime not particularly welcoming. There is warmer engagement with the UK, which will also be closer to their home country of Denmark. Indonesia, an energy-hungry country in desperate need of getting off coal, is also on the radar.

“I see the regulatory risks for our project as greater than the technology risks,” said Christiansen, the CFO. Indeed, being unlike anything else on the market, CA must find an open-minded regulator who take a collaborative rather than a prescriptive approach towards nuclear regulation. The inherent safety characteristics of MSRs is in its favor, however, says Christiansen. It also a reactor that does something very unusual: get rid of some of the regulator’s existing headaches by neutralizing nuclear waste.

A question I had was about how repairs would be done on the units, which are sealed tight, with no controls beyond a big “stop” button. “We simply wouldn’t bother with repairs,” said Christiansen. The units are so cheap that if anything at all goes wrong, the default is to drain the salts to the dump tank for recovery while the rest of the unit is treated like any other unit at end of life.

“That cheap?”

“I actually don’t like to talk about the ultimate financial potential…it makes us sound too crazy. But, if you look at the projections…yeah.”

But all that potential can only materialize if the computer models of fission activity CA is relying on ends up dovetailing with all the hands-on work they’ve been doing to yield an actual working demo reactor at the 1MW scale. The soonest that might happen if all the regulatory and technological stars align? 2025, according to the company. And the earliest possible date for the full-sized Waste Burner to be online? 2028, say the company. “When scalability has been reached, it can deliver energy at an expected cost below $40/MWh.”

THE ELEMENTAL TAKE

The thing that impressed me the most about Copenhagen Atomics is not the thorium, or even the molten salt. It’s their obsessively hands-on way of working. “Design-test-improve” is their philosophy and while on a start-up budget, they’ve managed to create a lot to be proud about.

The fact that they’ve already created products for sale — their highly-purified salts and molten salt loops — is huge to me. They don’t want to lean on the sale of those items, of course, they want to make energy! But income is income, and those sales create both credibility and extends their runway while they pursue their ultimate goal.

One thing I don’t like about them is that in some of their marketing material, they disparage today’s uranium reactors compared to their technology. I don’t think that’s the way to go.

The advantage to today’s reactors is that we know they work. With CA’s Waste Burner, we’re talking about a bet that a lot of things will turn out as they predicted. To take just one: the constant removal of fission products from the molten salt. Steenberg was pretty confident this wouldn’t be an issue. But with all respect, he hasn’t been able to put that to the test.

While acknowledging the limits of working on a reactor without radioactivity, it’s incredibly refreshing and unexpected to find a company that manages to rack up so much testing on everything that IS within their control. Yes. They are working with a lot of unknown unknowns. Yup. They’re leaning a LOT on computer models. But…

I know from my work as a renewables reporter that the average offshore wind farm costs billions of US dollars. For a fraction of the cost of just one windfarm, plus a friendly regulator, Copenhagen Atomic’s concept can get tested, with real fission activity. I hope they get at least that much.

What do you think of Copenhagen Atomic’s Waste Burner? Game changer? Pie-in-the-sky? Or something in between? Leave a comment below. Also going forward I’m going to stop being lazy and publish Elemental Energy on the weekly! Tell me what you want to know!

This substack is an absolute gem. This particular article makes me consider applying at CA. Angelica, you're cut on the patron of the bright, honest and good-spirited humans that make our species great :)

Thanks for the illuminating work.

What's a good writeup on the basics of an MSR?